Food waste ‘soup’ proposed to food waste producers

Food waste producers are being offered the chance to contribute to the first anaerobic digestion feedstock designed to give a guaranteed production of biomethane.

The blended ‘soup’ – manufactured from food waste and sold to anaerobic digester (AD) operators under the Ch4rger brand – is mixed to a fixed specification. It provides AD operators with a consistent product, which supports a finely-tuned biocommunity that ‘eats’ waste to produce valuable biomethane. This keeps plants at peak performance and leads to a more regular production of gas.

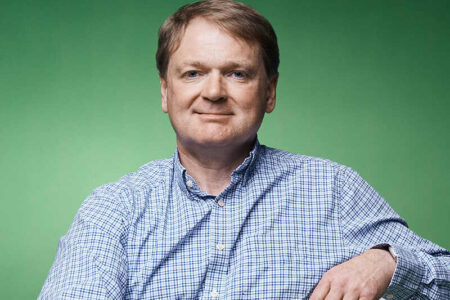

Nigel Lee, general manager at Amur, which produces Ch4rger, says, “We have been generating profitable disposal routes for co products for over 30 years, while providing the skilled technical know-how to ensure that animals are fed the right blends for peak performance. Through Ch4rger, we have applied our extensive biological expertise to offer a sustainable solution for those wastes that may not be suitable for animal feeds.

“If customers choose to send animal by product and other wastes to Amur, they can be certain that their material will not just be a tick towards sustainability, any food waste used to make Ch4rger is having a significant impact on the productivity of the AD plant it feeds. We also work with a waste management partner to ensure that our suppliers benefit from excellent levels of packaging recycling.”

Lee explains that many AD plants struggle to optimise gas production. This is largely due to variance in the feedstocks fed to the plant.

Amur has also demonstrated its long-term commitment to AD by building its own gas to grid site. The 3MW facility in Yorkshire is processing 60,000 tonnes of food waste, to deliver 40,000 MwH per year.

Lee concludes, “We are unique in being able to mix a waste to a specification. This provides AD operators with a consistent product, which allows the plant to fulfill its potential. For food manufacturers who want to play a part in the circular economy, and really make the most of their co-products, it is an exceptional opportunity.”