Full Stream ahead for drinks firm

Warehouse Loading Docks inside

A manufacturer and supplier of home carbonation systems has installed a new Zetes logistics execution solution in its Israeli production campus, to ensure ‘precise identification of stock and full visibility of its production line’.

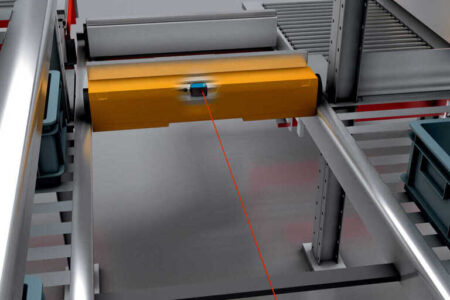

SodaStream’s production site in Israel contains conveyor belts, which transport cases from six lines out to their logistics centre. Previously, staff manually counted the cases as they moved from the conveyors prior to being loaded for delivery.

However, this process was error-prone and left an information gap when staff were unable to effectively analyse the exact numbers at the end of each shift, says the drinks manufacturer. So it sought a solution that could monitor and accurately calculate stock as it moves through the production line.

It chose Zetes’ palletisation software, ZetesMedea, which uses high-quality camera identification to scan the barcodes on each case, providing SodaStream with a reliable and accurate inventory count. The solution also reads and decodes 100 per cent of the cases as they travel on the conveyors.

The data, which includes product information, is automatically captured in real-time, allowing managers to monitor and proactively optimise performance processes.

In addition, ZetesMedea integrates with the existing legacy software providing a broad and accurate picture of item movements. The solution has also extended capability by monitoring the output volume of cases on the lines, and calculating the production rate during a shift, informing staff in real-time of KPI performance.