Theegarten-Pactec at interpack 2020: faster, flexible primary and secondary packaging

Theegarten-Pactec will be presenting two newly developed, high-performance packaging machines.

At Stand B51 in Hall 1, the Dresden-based company will present its BLM innovation: the first cartoner from Theegarten-Pactec, which can keep pace with the high speed of the primary packaging machines, as it can secondarily pack up to 2,000 individual products (120 cartons per minute). Another highlight is the new CHS modular high-performance packaging machine for chocolate products. It now packs up to 1,800 products per minute instead of the previous 1,200 and can also be adapted even more flexibly and therefore more efficiently to longer, higher or wider products.

The cartoner allows customers to operate their primary packaging machines at full capacity – even small products can now be processed with a high output.

At the interpack, Theegarten-Pactec will demonstrate how effectively the machine works using stock cubes. The application at the stand presents the individual production and packaging steps live – from powder feeding (AZO company) to the press (Romaco Kilian company), which forms the well-known tablets from the powder. The tablets are then packaged by the BCW3 primary packaging machine in side fold at a speed of 1,400 pieces per minute, before being secondarily packaged at the same speed by the BLM cartoner in cartons (60 pieces per carton).

New modular, high-performance packaging system

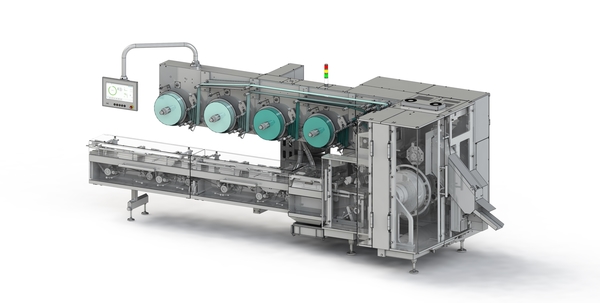

As a further highlight, Theegarten-Pactec is exhibiting the modular CHS high-performance packaging machine – specially developed for the gentle packaging of chocolate products and now achieves an output of up to 1,800 instead of 1,200 products per minute.

At the exhibition stand, Theegarten-Pactec will demonstrate how chocolate pralines with an output of 1,600 products per minute are packaged in the “Protected Twist” (sealed double-twist wrap) folding mode.

The CHS is especially flexible with regard to the possible folding types: Nine different folding types are possible. Additionally, the machine allows quick changes of folding type and format within only four hours. These can be carried out by only one employee.

Thanks to its flexible design, the machine is particularly suitable for different products and folding types that are in seasonal demand.

In addition to the many benefits of the product innovations, visitors to the fair will also be able to see Theegarten-Pactec’s entire advanced product portfolio.