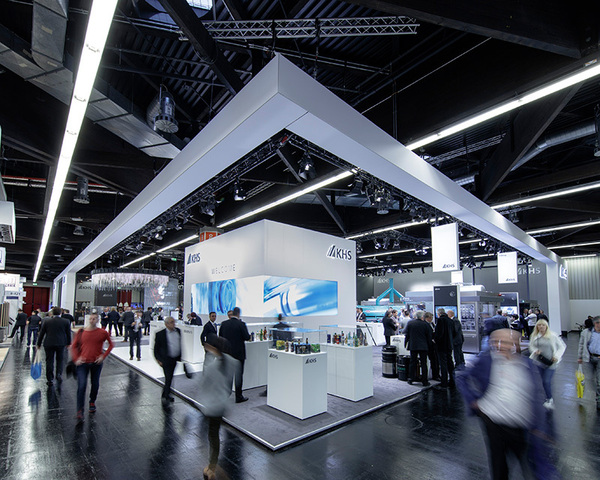

KHS presents a new can packaging system in its premiere at interpack

The KHS Group will be presenting “pioneering” technologies for primary and secondary packaging at the trade show in Düsseldorf, Germany.

A new can packaging system will form the centre-piece of the KHS booth. With its further developed palletiser infeed the turnkey supplier will also be consistently continuing to provide greater sustainability, efficiency and process reliability in production. In addition, smart, convincing service solutions for the long and reliable operation of plant machinery will be in the spotlight.

“As a specialist for packaging equipment we’re constantly further developing our systems and solutions with the aim of saving on materials and providing efficiency in operation. Here, we take all packaging materials into account – whether these be plastic, cardboard or paper,” says Dr. Johannes T. Grobe, CSO for the Dortmund engineering company.

“In this way the KHS Group wants to continue to consolidate its position as a reliable partner for flexible and future-proof packaging systems.”

At interpack the systems supplier will present turnkey systems, which satisfy customer demands for packaging alternatives that are both economical and environmentally friendly.

The focus of interpack 2020 will be on a new development in secondary packaging that, according to Grobe, “usefully supplements the KHS packaging portfolio and thus further strengthens it.” This format can replace the shrink film used to package packs of 12 or 24 containers for transportation. The first stage in this new project has been successfully completed together with a big, international beverage producer.

With this further development KHS wants to help its customers to save more CO2 in the production process and the packaging itself and in this way reduce their overall ecological footprint.

Intelligent control

An intelligently controlled KHS palletiser with a pressureless container infeed optimises time sequences and simplifies work steps in production. Besides especially gentle pack handling the elimination of railings facilitates and shortens format changeovers. The machine can also be used for returnable containers.

KHS services extend machine service lives

KHS is also continuing to build on its consulting expertise in the service sector, for instance concerning old machines with discontinued components with the aim of extending the machine’s service life. For instance, older KHS palletisers containing discontinued KUKA KRC2 control units can be operated without any problems for many more years by converting them to new controllers. The supply of spare parts is therefore also ensured.

KHS will be at interpack from May 7 to 13, 2020, in Hall 13, Booth A31.