GEA launches new SmartPacker Twintube

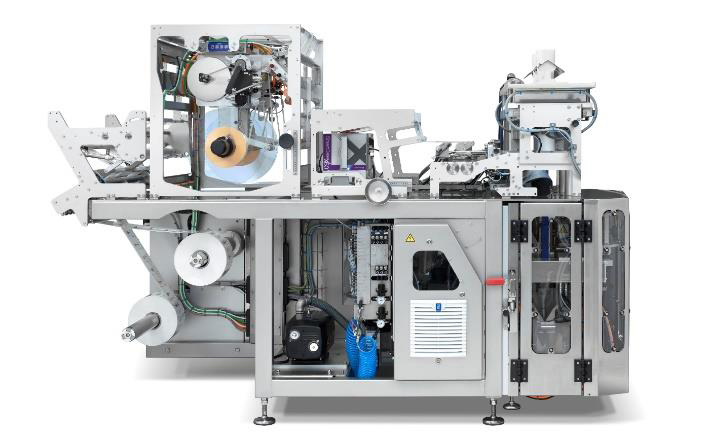

GEA has launched its new SmartPacker TwinTube vertical packaging machine onto the UK market. The entire machine has been redesigned as a future-proof modular system with increased functional efficiency promoting higher operational uptime and ease of use. The updated version reduces operational costs and energy use due to sealing technology advances. Plastic as well as functional paper can be used for bag production.

The TwinTube is a continuous motion vertical machine, suitable for packaging small-sized food products such as confectionery, dried fruits and nuts, and other on-the-go products in pillow bags of different sizes. The machine is part of a complete packaging process with upstream and downstream equipment operating in a dry manufacturing facility. It operates with two parallel forming tubes, achieving combined speeds of up to 500 bags per minute (weighing 10-18g each). It is also possible to run a different film reel for each tube, meaning calorie packs of different widths or designs can be simultaneously filled. A new feature to the machine is the Jumbo Roll, which allows film reels of up to 100kg to be used for long production runs, which boosts operational efficiency.

The new TwinTube has a modular construction which allows customers to easily add new options and upgrade their machine, thus prolonging the life span of the system. In addition, the new model boasts increased operator friendliness by introducing toolless adjustment features which helps achieve shorter change-over times and proven error free setup of the machine.

“This includes printers, labellers and the vertical sealing unit,” explained Martijn van de Mortel, product manager, Vertical Packaging at GEA. “With these new updates, GEA can meet customer demands in terms of automated process control, less operator dependence, more uptime and operational efficiency,” he added.

Some of the advantages of the new TwinTube packer, according to GEA, are as follows:

Automatic web tracking

The new SmartPacker TwinTube is also equipped with automated web tracking. This means that if the film deviates from its path due to, for example, variances in the film roll, the feature will correct the direction of the film automatically, without the need for manual adjustment. Ultimately GEA says this safeguards the quality of the resulting bags, whilst saving on downtime.

Reinforced sealing for more flexibility

The new SmartPacker features a jaw closing mechanism, optimised heating unit and a vertical rotational seal unit, promoting robust packing performance and excellent tightness of the pack seals. The jaw closing mechanism offers over three times the sealing force of the previous model and can apply 6000N. This gives the opportunity to use thicker films, or films with more diverse characteristics in terms of sealing requirements.

Due to the more stable suspension of the longitudinal seam unit and the reproducible and precise positioning by spindle and ruler, shorter changeover times are possible when switching formats or foils. “With this development producers will be able to work with more challenging films and thus be able to give retailers and consumers what they are looking for in terms of bag quality, with an even wider range of film materials,” stated van de Mortel.

Easy labelling, operation and maintenance

The new GEA SmartPacker TwinTube is optionally equipped with a new, fully integrated GEA TiroLabel unit, which makes the machine more compact on the factory floor. The dedicated labelling unit delivers a speed of up to 180 labels per minute at a width of 150 mm and achieves millimetre precision during labelling. The label roll has a quick-release operation, which means it can be changed in seconds with minimal downtime.

Comfortable to operate and maintain

The machine features an innovative open design with double-hinged doors for easy access and see-through panels providing maximum visibility of the sealing area. Full access and easy maintenance are made possible via the machine’s hinged front-plate – to which the sealing arms and vertical seal are attached – and which can be fully opened. This, according to GEA, ensures all items requiring maintenance can be easily reached.

For more information, visit: gea.com.