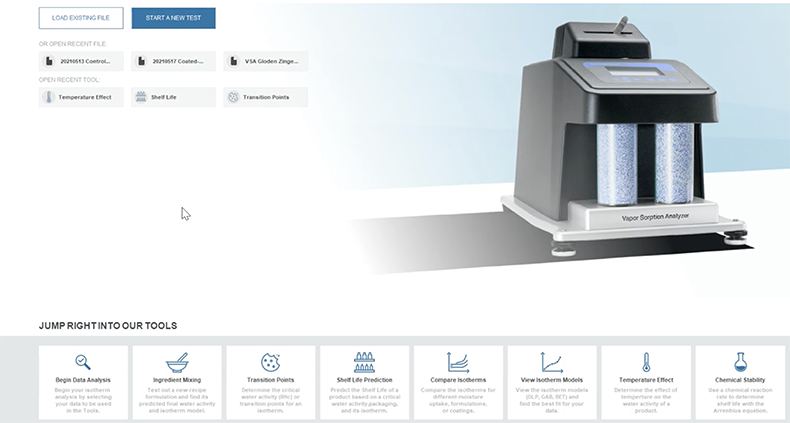

METER Group unveils major update to AQUALAB Vapor Sorption Analyzer software

METER Group Inc USA has unveiled a major update to the AQUALAB Vapor Sorption Analyzer (VSA) Moisture Analysis Toolkit, enabling food and pharma companies to harness analytics and predictive modelling that accelerates product formulation, maximizes cost-efficiency of packaging and extends shelf life.

The AQUALAB VSA Moisture Analysis Toolkit (MAT) is a first-of-its-kind, intuitive, full-featured modelling solution that transforms moisture data into solutions using research-tested predictive models.

This software helps overcome key water-related research and development challenges. It is particularly relevant as food manufacturers turn to high-tech solutions to increase profitability in the face of supply chain issues and consumer concern over safety and sustainability.

Like most manufacturers, food producers are increasingly impacted by supply chain shortages. The pandemic has exacerbated existing ingredient sourcing problems caused by climate change. With the Moisture Analysis Toolkit, manufacturers can use high-resolution moisture data to predict the effect of new ingredient candidates on moisture in the final product.

“In a new supplier situation, our clients rely on the toolkit to make faster decisions and react quickly to new ingredient sourcing,” says METER executive vice president Takuya Ohki. “That’s what the toolkit is all about—faster, data-driven decisions that allow our clients to stay competitive in a fast-changing marketplace.”

Ohki says that data-driven decision making is at the heart of the MAT, which includes tools for selecting the correct packaging and determining shelf life. “Historically, companies have tended to over-package and set a conservative best-by date. Now consumers are pushing companies to address issues of 30-40% waste in the food supply—while still demanding a mould-free product. Tackling safety and sustainability in tandem requires our best use of science. Too much of this research is still not implemented in industry. The Moisture Analysis Toolkit is something designed to make this science immediately accessible, to allow food manufacturers to solve these problems today.”

The MAT takes advantage of a unique moisture map created by METER Group’s AQUALAB VSA. The VSA generates a high-resolution isotherm called a Dynamic Dewpoint Isotherm (DDI) curve. DDI curves can save companies months spent identifying a critical water activity in low and intermediate moisture food and pharmaceutical products, because they clearly illustrate the change in sorption properties.

While competitor instruments use just the DVS method, METER Group’s MAT not only delivers DVS isotherms, but it also provides truly dynamic high-resolution DDI isotherm curves, uncovering granular details which have never been seen before. Unlocking access to these critical insights allows for more precise formulation, more accurate predictions, and more complete product knowledge.

The business benefits and value are significant. For example, a dry ingredients company struggling with excessive labor, time, and space spent on shelf-life studies reduced the amount of physical shelf-life tests by 75 percent, cutting expenditures on testing from $300,000 to less than $50,000 per year.

METER’s Moisture Analysis Toolkit also lets manufacturers work backward, picking a final water activity that maximizes shelf life and then getting guidance on specific formulation decisions around ingredient selection. This not only makes the formulation process more precise, but also speeds it up.

A cold press bar company used the MAT with VSA-generated DDI isotherms to assess moisture migration during the R&D process, allowing them to release new products 5x faster and bring new flavours to market before competitors.

“We see our clients succeeding from a profitability standpoint, but to me, that’s only part of the equation,” says Ohki. “The Moisture Analysis Toolkit empowers food and pharma companies to eliminate waste and inefficiencies across their respective supply chains on an unprecedented scale. That’s about more than profitability—it’s about putting existing science to work on the big problems we have to tackle as a society.”