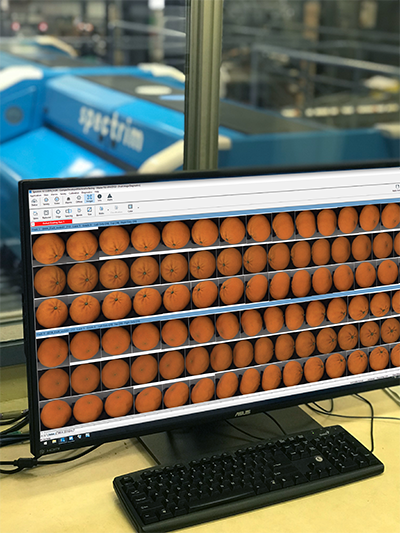

Tomra Food introduces SmartGrade on its Spectrim platform

Tomra Food is introducing SmartGrade on its Spectrim platform. According to the company, the new system puts the packhouse in complete control of grading with such accuracy that it is able to pack fruit to maximise sales by matching very precisely the specific requirements of the individual customers. It identifies each blemish and defect type, and maintains consistent grading performance even when there is high variability in the quality profile of incoming fruit batches. US-based packer Prima Frutta is an excellent example of how SmartGrade takes grading accuracy to an entirely new level, delivering significant improvements in efficiency, yields and profitability with all commodity types, says the company.

SmartGrade allows multiple inspection passes of each image of the fruit, with individual defects assigned to each pass and the settings optimised based on that specific defect. This results in extreme accuracy in identifying individual defects and blemish types – even with hard-to-detect defects.

“The advantage is that you can look for different things on each pass, rather than having to bundle them together,” explains Kurt Bagby, Research and Grading team lead, R&D at Tomra Fresh Food, part of Tomra Food. “This is very useful when defects occur together or on top of each other. It allows you to get very granular in your grading.”

“The advantage is that you can look for different things on each pass, rather than having to bundle them together,” explains Kurt Bagby, Research and Grading team lead, R&D at Tomra Fresh Food, part of Tomra Food. “This is very useful when defects occur together or on top of each other. It allows you to get very granular in your grading.”

The multiple passes targeted on individual defects means that SmartGrade maintains a consistent grading performance when there are variations in incoming fruit batches.

“Incoming fruit and the distribution of defects within the fruit can change a lot,” adds Bagby. “Systems rely on compromise settings to deliver the required grade pack. Some defects will be detected better than others and good fruit will be more likely to be rejected as a result of this trade-off. Also, the system will be in trouble if the fruit batch presents new or unusually high levels of a specific defect that wasn’t expected. With SmartGrade we can atomize the grading around each defect of interest, without compromises, so that we can get the best performance for every one of them.”

SmartGrade also helps packhouses address the issue of labour shortage, as it requires fewer people on the line for manual grading due to its ability to maintain high accuracy with high variability in incoming fruit batches. This is particularly valuable at this time, as the pressure to reduce labour in packhouses to ensure safe working conditions with social distancing measures is due to the Covid-19 pandemic.

SmartGrade performs equally well on all commodity types, according to Tomra Food: from apples and stone fruit – including cherries and avocados – to citrus and kiwi fruit, as well as potatoes and onions.