GEA targets SMEs with compact CookStar First spiral oven

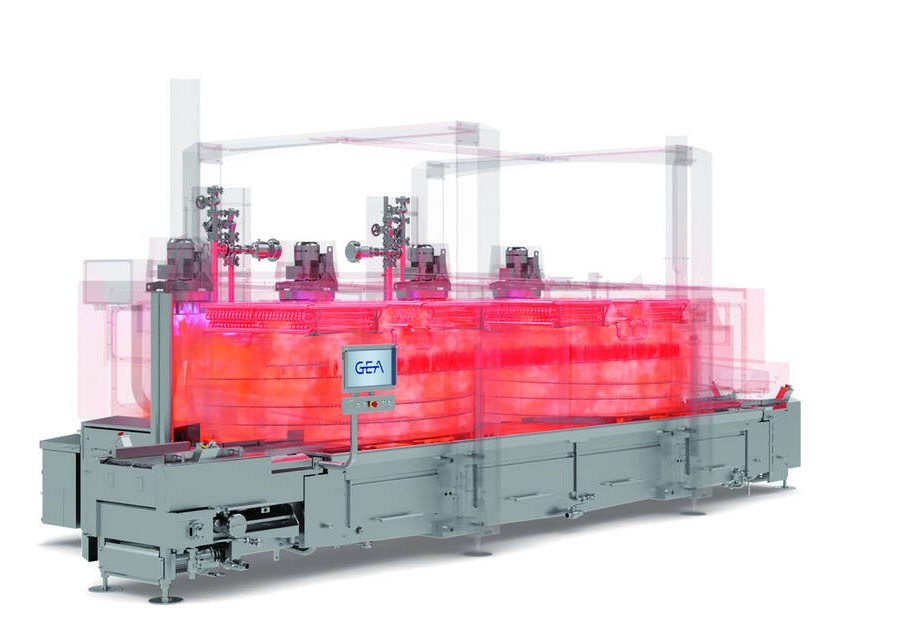

GEA is targeting smaller processors with the launch of CookStar First, a compact twin‑zone spiral oven designed to give SMEs access to the kind of thermal performance normally associated with large industrial lines.

The system marks an extension of the CookStar portfolio, offering a scalable route for producers moving from linear to spiral cooking while seeking tighter control over quality, consistency, and resource use.

The system marks an extension of the CookStar portfolio, offering a scalable route for producers moving from linear to spiral cooking while seeking tighter control over quality, consistency, and resource use.

At the heart of the new model is a twin‑zone configuration with integrated booster impingement, combining horizontal and vertical airflow to deliver far more even heat distribution than conventional ovens.

GEA reports core‑temperature variation across the belt of around 1°C, compared with swings of up to 6°C in typical systems. That stability allows processors to shorten cooking times by 10–30 per cent without compromising colour or internal doneness. Throughputs of up to 1,700 kg per hour and yield improvements of up to three per cent position the oven as a meaningful productivity upgrade for mid‑scale plants.

GEA reports core‑temperature variation across the belt of around 1°C, compared with swings of up to 6°C in typical systems. That stability allows processors to shorten cooking times by 10–30 per cent without compromising colour or internal doneness. Throughputs of up to 1,700 kg per hour and yield improvements of up to three per cent position the oven as a meaningful productivity upgrade for mid‑scale plants.

Energy efficiency has been a major design focus. GEA has re‑engineered the oven balance with an intelligent active exhaust system, revised airflow management, and adjustable product gates to minimise leakage and maintain stable thermal conditions. More efficient water flow also supports reuse. Together, these measures cut energy and water consumption by up to 12 per cent, earning the CookStar First the company’s “Add Better” label for resource‑efficient equipment.

For operators, the oven’s digital layer is intended to simplify control and support optimisation. The GEA SmartControl HMI provides real‑time process visibility, alarm management, and a 24‑hour event timeline, and can be connected to GEA Insight Partner for remote diagnostics and service planning. This level of transparency is increasingly important for SMEs looking to professionalise their processes and reduce downtime.

A compact footprint — less than 3.9 metres in height — means the oven can be installed in existing facilities, including brownfield sites with limited ceiling clearance. Its broad application range, from steam‑cooked products and coated poultry to plant‑based items, baked goods, and ready meals, gives smaller processors flexibility as they diversify portfolios.

A compact footprint — less than 3.9 metres in height — means the oven can be installed in existing facilities, including brownfield sites with limited ceiling clearance. Its broad application range, from steam‑cooked products and coated poultry to plant‑based items, baked goods, and ready meals, gives smaller processors flexibility as they diversify portfolios.

CookStar First sits beneath the original CookStar, which offers smoking capability and higher capacity, and the CookStar Turbo, designed for large‑scale roasting and throughputs of up to 12,000 kg per hour. All models share a common footprint, allowing producers to integrate the new unit into existing CookStar lines or scale up as demand grows.

GEA is supporting the launch with access to its food technologists, operator training, and global service network, aiming to help SMEs accelerate commissioning, refine processes, and maintain long‑term performance.