Chilean company installs Tomra 5B sorter in berry processing plant

Chilean company Vitafoods has put its trust in Tomra Food once again in order to optimise its sorting process and continue to offer premium quality frozen raspberries. Ten years ago, Vitafoods (formerly Hortifrut and Alifrut separately) opted for the brand for its blueberry production and acquired Tomra technology. On the back of its positive experience, the company has opted for the Tomra 5B, a sorter ideal for products that, like frozen raspberries, require delicate handling and high precision when sorting.

Chile is one of the largest exporters of frozen berries and raspberries. “The raspberry is the product with the highest added value when it is whole. When it breaks, a by-product called crumble is produced, which has a considerably lower value. Being able to automatically process IQF raspberries without damaging them or losing value is a great advantage for processors. In addition, our technology is flexible, easy to use, and offers a high yield,’” explains Paola Arévalo, sales manager Tomra Processed Food at Tomra Food Chile.

Vitafoods is the largest berry processor in Chile and aims to consolidate soon its position as the country’s largest frozen fruit exporter. It has chosen a Tomra 5B for the grading of its delicate frozen raspberries. This is a segment with an upward trend. As Fernando Larios, COO of Vitafoods explains: “Consumers, especially during the first wave of the pandemic, were looking for healthy products that would also have a longer shelf life, such as the IQF raspberry.”

Vitafoods was born from the merger of the Hortifrut and Alifrut frozen food businesses. Today it exports 93% of its production and relies on more than 300 producers, which positions the company as one of the most powerful companies in the market.

It says its main asset is undoubtedly quality. “At Vitafoods we offer premium quality. This allows us to work with the most demanding market, such as the United States and Europe, or to meet the most demanding requirements of Asian countries such as Japan. In order to deliver what our customers expect from our brand, it is essential to have the right technology.”

In terms of its customer base, the company’s sales from the retail channel (supermarkets and retail outlets) versus bulk sales have grown to almost 50% – an achievement the company says it is very proud of. As far as the type of product is concerned, Vitafoods offers two types of fruit: organic and non-organic because, as Fernando Larios explains, “in Chile we have the enormous advantage of an ideal climate that gives raspberries a superior flavor. In addition, our natural borders create a barrier against pests. This allows for greater phytosanitary control, which enables us to sell both products.”

Regarding the trends in the international and domestic raspberry markets, Fernando Larios explains: “The way the agricultural sector operates is changing: we are seeing a trend towards greater use of technology and self-cultivation in the main markets. This makes it possible to achieve the desired product volumes, avoid fluctuations in quality and not depend on suppliers.”

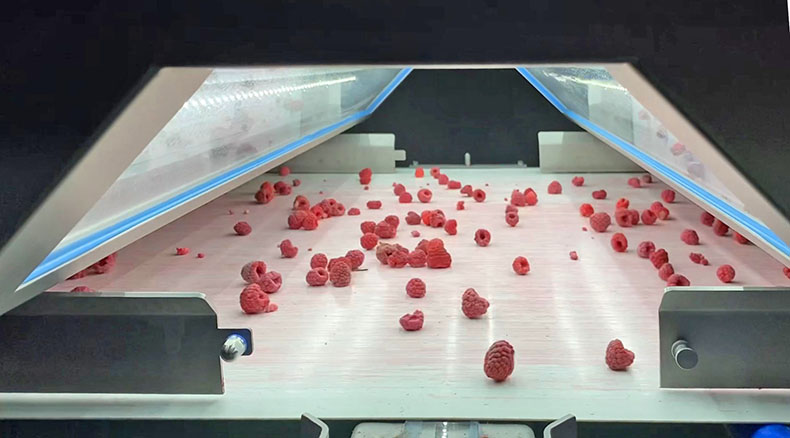

The Tomra 5B recently installed at the Chillán plant has become an essential tool for Vitafoods for sorting frozen raspberries. This Tomra Food belt sorter is designed to remove even the smallest foreign materials and defects in fruits and vegetables, guaranteeing the plant’s food safety.

“I truly believe that the Tomra 5B is unrivalled. It detects the main raspberry defects, such as albinism or sun damage, with high efficiency. Its ability to detect plant matter such as leaves, flower debris, or foreign matter such as plastics and wood, combined with its gentle handling that ensures the product doesn’t break, bring true innovation to its machine segment,” comments Fernando Larios.

“Before we installed the Tomra 5B, we had to assign 18 workers to manual sorting, and they processed 2 tons per hour. With the Tomra 5B we have been able to process 2.6 to 2.8 tons of raspberries per hour, and we only need 6 workers for this sorting stage. This means we have been able to redeploy the staff to later stages in the process,” says Larios.

The Tomra 5B also allows the operator to easily adjust the sorting criteria to suit the quality required by the customer and the desired product. By introducing new functionalities that deliver unprecedented accuracy, the Tomra5B improves production and increases profitability.

Fernando Larios says: “We are really satisfied with the purchase of the Tomra 5B for our new frozen raspberry line. It is a model that stands out for its excellent design. It treats the product extremely gently, and prevents it from being damaged by free falling. It is a highly hygienic machine, which is now more important than ever. Its software is more intuitive than that of previous sorters. Thanks to all these advantages, we have also set up a program for sorting blackberries on this line, as it can process less delicate products such as blackberries of frozen strawberries.”

Paola Arévalo confirms: “For this particular application, with IQF raspberries, the great advantage of the Tomra 5B is the exceptionally gentle treatment, as it is a belt sorter and not a free-fall machine like other solutions on the market. The combination of high-resolution RGBI cameras with 360-degree view and laser technology makes it the most powerful machine on the market, able to detect color defects (albinism), unwanted plant material and foreign matter with the highest efficiency and resolution. In addition, the interface of the Tomra 5B provides operating flexibility and is easy to set up and operate.”

Vitafoods’ raspberries are hand-picked in the field and, when they arrive at the plant, they undergo quality control. Once there, they enter the system and they are cooled as quickly as possible in the freezing tunnel. Then, they pass through a vibrating machine where crumble is separated from the whole fruit. The latter goes to the Tomra 5B. The discarded fruit goes to the grinder and is sorted together with the crumble in the Blizzard and the Helius.

Fernando Larios explains how the purchasing process developed after several tests: “Initially, when we went to view the equipment at Tomra’s demonstration site in Santiago de Chile, we were looking for alternative solutions for sorting our product, both in terms of volume and quality. We first tested the sorter with a small volume and it worked excellently. Then we tested it with larger volumes and at more demanding rates, and we were extremely satisfied. Fortunately, the Tomra 5B was already in place when the global health crisis started, so we have been able to operate with a certain degree of normality in spite of everything.”

“We have had Tomra machines for ten years. The equipment as a whole ensures that the process runs smoothly. The Blizzard and the Helius do their job to ensure that the crumble comes out completely clean, optimizing costs and avoiding product losses. The rest, foreign and vegetable matter, is discarded,” explains Fernando Larios.

Calibration and training are also key aspects for Tomra Food. “Calibration makes a big difference to the final result, so the first adjustment of the season is crucial, because you ensure that the next run will need less calibration. They are very stable machines and they are capable of entering parameters for new defects as they appear. As far as training is concerned, Tomra’s technical team evaluates our operators and tells how much training each of them needs to improve the process,” says Fernando Larios.

“At Tomra Food we are always at the customer’s side: the experience of our highly-trained after-sales team, and our local presence, mean that we are always attentive and react quickly to any need,” concludes Paola Arévalo.