Mecatherm and ABI Ltd launch new bagel production line

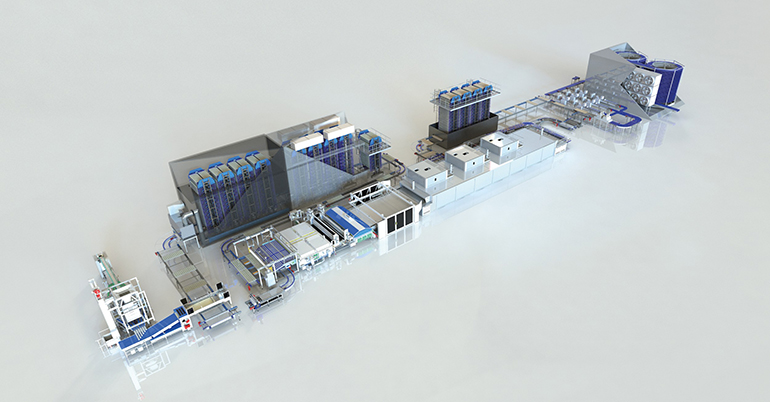

The new Mecabagel production line. Image credit: Mecatherm

Mecatherm, one of the world leaders in automatic production lines design for industrial bakery, pastry and patisserie, has joined forces with ABI Ltd, the world leader in industrial bagel production equipment, to launch Mecabagel, an industrial production solution for bagels that is reportedly unmatched on the market.

This partnership (operational in Europe, Asia, Australia, Mexico, South America, Middle East and Africa) is a world first which has created a line specially designed for bagel production so that manufacturers can produce bagels as close as possible to a traditional method, while optimising industrial performance.

“The bagel market is growing, particularly in Europe and Asia-Pacific. There are many varieties and take-out bagel sandwiches are a trend that is currently developing all over the world. The potential of this market is encouraging and especially interesting for our customers looking to diversify production”, explains Olivier Sergent, president of Mecatherm.

“We know the ABI LTD teams well and we have already worked on several bagel line installations together because our equipment is complementary. It seemed to be a smart choice to combine our expertise and work on a shared product offer to give manufacturers a quality solution specific to the manufacture of bagels. That is how Mecabagel was born”.

Alex Kuperman, CEO of ABI Ltd, adds, “We are delighted with this partnership for market development. Our in-depth knowledge of the bagel and our experience of the product for over 30 years, combined with Mecatherm’s recognised know-how in baking, means that we can offer a particularly efficient production line to manufacturers who want to enter the buoyant bagel market.

Alex Kuperman, CEO of ABI Ltd, adds, “We are delighted with this partnership for market development. Our in-depth knowledge of the bagel and our experience of the product for over 30 years, combined with Mecatherm’s recognised know-how in baking, means that we can offer a particularly efficient production line to manufacturers who want to enter the buoyant bagel market.

“The Mecabagel production line is designed to meet the specific characteristics of the product at each stage of production. The quality of the finished product, produced as close as possible to traditional methods, is excellent. And because the processes are optimized, fully automated and controlled by intelligent tools, the Mecabagel line delivers a high level of industrial performance. Finally, the flexibility of Mecabagel makes it possible to fine tune the process to obtain the finished product required: New York bagels, Montreal bagels or a bagel specific to a particular country or region”.

Mecabagel is a complete solution that is flexible and focused on the production of authentic products. It is a comprehensive production line for bagels, from the start of the assembly line to deep freezing. Mecatherm provides the equipment for dough proofing and retarding, product sampling, baking, cooling and freezing. ABI Ltd supplies equipment for cutting and forming the dough and, further down the line, after fermentation, equipment to boil, seed and dry the product before baking.

For more information about the Mecabagel production line, visit: www.mecatherm.fr/en/lines/mecabagel-line.