Intense Natural Quality Ingredients with Cold Concentration Process

The natural food flavours market is a dynamic and expanding market due to the increasing consumer demand for natural, healthy, new and sustainable products. Natural flavours in concentrate form are used in food and beverages in order to enhance the taste and quality of the products. However, using thermal evaporation during the concentration stage leads to product degradation of the sensory profile of the natural extracts and juices. Manufacturers of natural flavours must innovate and adapt to benefit from the opportunities in this growing market.

The evapEOs process of cold concentration developed by EDERNA for the food & beverage and biotechnology markets ensures high levels of concentration with high levels of preservation of the sensory and functional properties while offering a low environmental footprint.

Cold concentration vs. evaporation

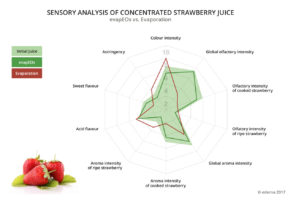

The cold concentration technology by evapEOs has been compared with standard concentration by vacuum evaporation.

Trials were carried out on fresh strawberries. Strawberry flavour, easily identifiable, is complex as the characteristic aroma of a fresh strawberry is the result of several different aroma compounds.

The juice was extracted from the fruit puree and pectins were removed using enzymes, followed by clarification using centrifugation and then sieving at the level of 150 microns. The clarified juice was concentrated from 9° Brix to 65° Brix comparing both processes: evapEOs at 20°C (70°F) using, on the one hand an evapEOs micro-pilot unit and, on the other hand, vacuum evaporation at 60°C (140°F) using a laboratory rotary evaporator, a device that flavour producers consider as a valid laboratory scale equivalent of their industrial grade thermal evaporators. Samples of concentrates were pasteurised at 77°C (170°F) during 1 minute.

The sensory profiles of the samples were evaluated by a panel of tasters from an independent French sensory analysis laboratory certified by COFRAC, France’s sole national accreditation authority. Samples produced by the two methods of concentration were graded according to ten different parameters. Results are shown in the radar chart.

As a global result, the sensory profile of the concentrate produced using evapEOs cold concentration is very close to that of the initial strawberry juice, contrary to the result achieved by standard concentration. The evaporation lead to a significant degradation of the organoleptic profile, in particular a loss in olfactory and aroma intensities.

Additional Benefits

Apart from the sensory advantages, cold concentration also provides nutritional benefits. Numerous trials have shown far higher retention levels of antioxidants, anthocyanin and vitamins than those achieved with thermal evaporation.

Process co-development

EDERNA has set up a testing platform including a fleet of micro-pilot and pilot units for the evaluation and development of its process for the applications of our customers. A major advantage of the technology is the linear scalability of the process. From pilot scale evaluation, a full-scale production unit can be designed to meet the customer’s specifications.

evapEOs Pilot scale Unit

Conclusion

F&B manufacturers are thus able to market new natural products of higher quality than the standard ones that meet the new trends of the consumer.

EDERNA, a membrane technology company based in Toulouse, France, has developed the evapEOs cold concentration process, the winner of the Best Innovative Process Award in the Global Food Industry Awards 2016 organized by the International Union of Food Science and Technology (IUFoST). EDERNA offers to F&B industries and biotechnologies a full range of evapEOs systems under license, with worldwide technical and process development support.