Fixed weight tray packing

Ishida Europe has extended its range of solutions for poultry, meat and fish packaging with the launch of a system that improves yields and efficiencies in the packing of fresh food pieces.

The new RobotGrader combines weighing and pick and place technologies to grade products of varying weight and pack them to a fixed weight straight into the tray. The system reduces giveaway to less than 1% per pack and can correctly place and orientate the pieces, at speeds of up to 320 pieces per minute. By comparison, a manual operation can be extremely labour intensive with a single operator only able to pack 30 pieces per minute, and where overfill can be anywhere from 5% to up to 20%.

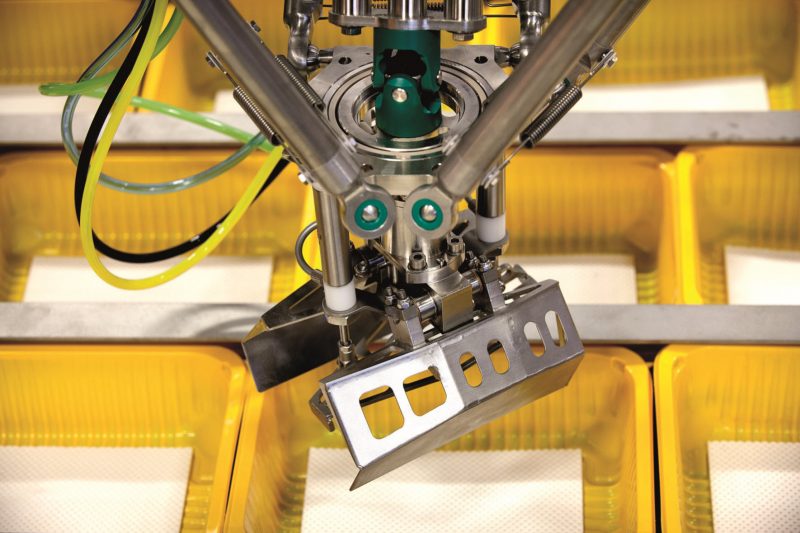

The RobotGrader is weighing products on a belt weigher. The information is then fed into the system’s sorting algorithms that determine the robot’s selection of the pieces. The robot stores the information on a large number of weighed pieces and the system also optimises the number of trays within the reach of each robot, maximising availability from which to create each complete pack. The robot gripper has been designed to grasp each piece firmly but gently and to orientate it correctly in the trays; for example, placing two chicken drumsticks in opposite directions.

Depending on the model, the RobotGrader can handle two, three or four different tray types at the same time. In addition, the system can identify and sort pieces whose weight is unsuitable for tray packing, and direct these to bulk bins (which are integrated into the RobotGrader) as well as freezers, slicers and marinating operations.