Automated sausage loading

Multivac has developed a hygienic and efficient solution, which is also gentle on the product, for the automated infeeding, loading and packing of straight and uniform sausages.

The Multivac Centrifuge Feeder (MCF) enables handling costs to be reduced by up to 60% when compared with manual loading.

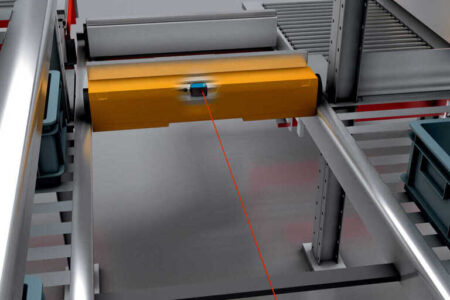

The solution comprises five components: the sausages are transported via an inclined conveyor to the centrifuge plate that is constantly turning. There, they are orientated at the outside edge of the plate by the centrifugal force and are taken up individually from the centrifuge ring. Then a V conveyor transports them to a downstream compartment conveyor that carries each product, individually and precisely aligned in a separate compartment, to the handling module. There, the gripper picks up the desired number of sausages and loads them into the pack cavity.

Up to 600 sausages per minute can be gently separated and loaded by the MCF. The output can be adjusted as required via the rotation speed of 30 to 60 revolutions per minute. The solution is suitable for single layer and multi-layer packs with any number and orientation of sausages.