Tna develops turnkey blending system for food products

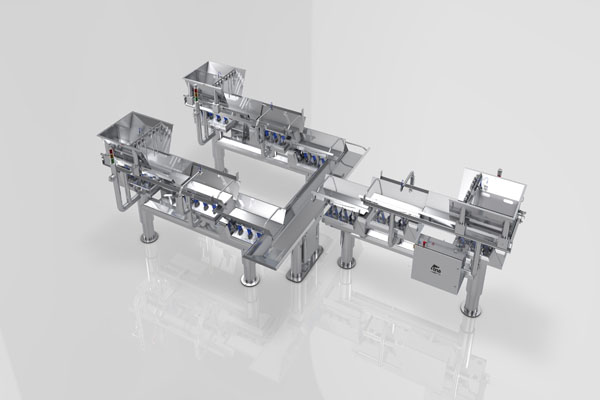

Tna has launched a new turnkey vibratory motion blending system to mix multiple dry or wet products.

The roflo 3 incorporates Tna’s weighing technology with an integrated load cell. The system has been developed to blend a range of products, including pasta and cereals, baked and fried snacks, nuts and dried fruits and gummy sweets, in addition to mixing fresh and frozen products such as salads or frozen vegetables, the company says.

Each integrated ingredient input module (IIM) of the roflo 3 features a compact design, comprising an infeed conveyor with hopper, control conveyor and weigh conveyor, offering some of the smallest factory footprints, Tna says. Depending on the individual requirements of their recipes, manufacturers can combine up to 22 IIM modules, all of which are centrally controlled by a single controls system.

The system’s washdown design with a stainless steel construction, no wearing parts and a mobile hopper facilitates cleaning, reduces maintenance and is intended to ensure superior equipment reliability. In addition, the roflo 3 operates on natural frequency, requiring minimal amount of energy for a more sustainable production process.

Roger Treacher, group product manager of conveying at Tna, says, “Product blending is becoming increasingly popular across the food industry. Whether manufacturers want to add some beef jerky to their trail mix for an extra protein boost or revive the sales of an existing product line by adding a new flavour to the bag, accuracy is key when it comes to product blending – especially when incorporating more expensive ingredients, where every gram counts.

“With our new Tna roflo 3 manufacturers can easily expand the concept of the traditional trail mix to other product categories while keeping an eye on their costs. What’s more, the system’s modular setup makes it easy to add more modules further down the line, all while taking up the least amount of floor space.”

The company says the roflo 3 is suitable for a variety of infeed methods, including manual, bulk or directly connected to the processing line. Furthermore, output can be fed onto a variety of distribution systems, including Tna roflo vibratory, horizontal or belt conveyors.