Sharp Systems and OspreyDeepClean join forces on hygiene solution

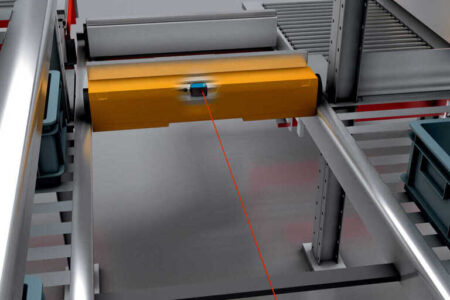

Sharp Systems is joining forces with OspreyDeepClean to develop a chemical-free hygiene solution for food manufacturers. The equipment will combine OspreyDeepClean’s dry steam cleaning technology with Sharp System’s product and ingredient handling conveyor systems. The resulting system would clean both sides of a mesh belt and sanitise and vacuum all surfaces.

When complete, it is hoped that the bespoke system will be able to be fitted to most production lines and a variety of conveyor belt widths and structures. Different sizes of cleaning heads may also be available in order to clean multi-width belts with only one system in place.

Thomas Stucken, Osprey managing director, said: “Dry steam is only ‘dry’ if it contains approximately 5% water. It therefore leaves surfaces virtually touch dry with slight residue. It dissolves grease, removes pathogens and reaches those areas where traditional cleaning methods struggle, sanitising every surface it touches.

“If our concept goes into production, the reduction in the use of water and complete absence of cleaning chemicals will generate significant cost savings for food processors and manufacturers as well as being more sustainable, helping businesses to improve environmental performance.

“By removing the need for traditional regular wash-downs, integrated equipment could reduce labour costs by up to 40% and significantly reduce down-time when changing between different food products. Because dry steam cleaning is also less aggressive than wash-down processes commonly employed, processing equipment lasts longer and operates more reliably, delivering further long term cost savings.”

It is hoped the equipment will be launched in the second half of 2014.