Aseptic drives benefit European fruit processor

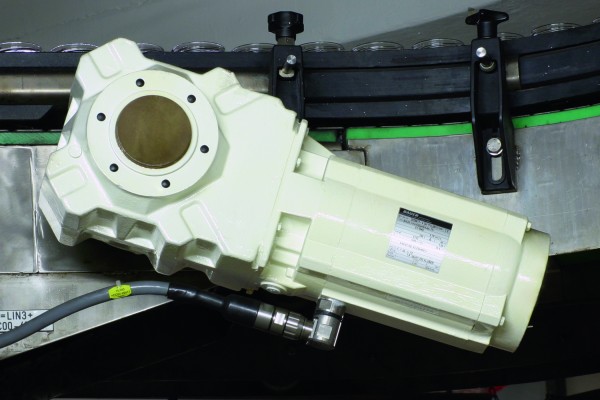

Bauer Gear Motor has supplied an IE3 aseptic drive solution to a jam and fruit spread production line, based in Germany, which needed to improve its glass jar filling line. The company was keen to specify equipment which would meet its strict hygiene standards but would also offer improved energy efficiency.

Aseptic drives are carefully designed for applications where regular wash downs are required to maintain a clean environment. The motor is designed so that fans and cooling ribs are not required, allowing for a smooth outer casing with a non-drive end which is sealed. This eliminates any dirt traps on the motor casing and prevents re-infection of the local environment caused by air movement from a cooling fan.

The design also includes a high level of ingress protection – up to IP69K – and the aseptic drive is painted using an acid and alkali resistant formula, which can withstand chemicals with a pH range of two to 12.